This week we sit down with Christine Dermody of Flex Energy Solutions, an alternative energy provider of reliable, clean power and waste heat recovery for commercial and industrial sites.

Tell us about Flex Energy Solutions and your key business objectives.

Flex Energy Solutions is an alternative energy provider of reliable, clean power and waste heat recovery for commercial and industrial sites throughout the world. Our efforts to reduce the carbon footprint of power delivery is driven by our goal of helping organizations and communities work toward clean energy and a healthy environment. We design and engineer clean, customizable power solutions in a collective reach toward a clean energy future.

In 2011 FlexEnergy acquired Ingersoll Rand’s Energy Systems business as part of an initiative to pair 250kW turbines with a prototype zero emissions device. FlexEnergy began to evolve as an exclusive manufacturer of small gas turbine generators and custom-fit heat exchangers. Flex Leasing Power and Service, a sister leasing business, was established in 2013 alongside additional growth capital for the manufacturing business. To date, Flex Leasing Power and Service maintains the largest owned and operated small gas turbine fleet delivering power to industrial and commercial operations today.

FlexEnergy and Flex Leasing Power and Service combined in 2019 to form Flex Energy Solutions. Together with a company staff of approximately 140, we provide robust, resilient power delivery systems and outstanding localized service.

How does your company support clients or customers in the energy space?

We provide on- and off-grid power that is always on, so our customers can save money and focus on their business without interruption. From our field service teams to our engineers and support staff, we work together to provide value to our customers with power solutions that are reliable, clean, and simple. Each feature of the Flex Turbine® solution is beneficial in helping our customers perform better. Combined, they deliver total product value.

In powering isolated microgrids, we offer a “FlexGrid” solution which deploys modular Flex Turbines to fit remote power site needs. With its wide operating range, paired with embedded controls, each Flex Turbine automatically and actively synchronizes to other units in the FlexGrid. Multiple Flex Turbine units operate seamlessly together to run distributed loads, while sharing and shedding power and maintaining stable grid conditions 24/7.

Each Flex Turbine unit is delivered with a generator braking resistor (GBR) for deploying reserve power, and to absorb excess power. Distributed pads on the FlexGrid provide constant, consistent, clean power, while the GBRs modulate individual units to follow cyclical, transient, and spike loads on the isolated grid.

When a producer expands production and requires more power, additional Flex Turbine units are simply added to the FlexGrid to run the increased load. The GBRs automatically operate to maintain the optimum load on each Flex Turbine, resulting in steady voltage, frequency, and power factor of production loads.

The FlexGrid solution offers built-in redundancy. If one unit is shut down, the remaining FlexGrid Turbines increase output to effectively carry the load. This FlexGrid design philosophy provides the automatic backup and adjustments needed so the production equipment can operate 24 hours a day, seven days a week, without shutdown.

The ability to provide round-the-clock power also means that Flex Turbines pair well with demand response programs. Flex Turbines can also operate parallel to the utility grid and come equipped with required paralleling gear in the control enclosure of each machine. This enables customers to offset the power they buy from the local utility.

For areas with the challenge of unpredictable utility power, the Flex Turbine comes equipped with Closed Transition Dual Mode functionality, which enables the provision of seamless energy during intermittent or extended grid power outages. Facilities can continue critical power supply or continue production and revenue generation regardless of the grid status. The security of energy provided by the Dual Mode Flex Turbine avoids shutdowns and costly plant restarts when the utility finally restores power.

Certified to the California Air Resources Natural Gas Distributed Generation Standard, Flex Turbines help clients and customers achieve simpler, faster permitting.

What is a key differentiator for your business?

Flex Turbines are robust, industrial-grade systems that burn cleaner than any gas turbines in their class. They transform associated flare and natural gases from oil and gas operations into a continuous source of clean electric power no matter the working conditions. Flex Turbines are the ONLY ‘micro’ turbine with a synchronous generator, providing enough kVA to start large motors. The wide fuel operability and low maintenance of Flex Turbines, requiring only one 8-hour scheduled maintenance interval per year, plus high reliability provide producers with proven 99+% runtime power. Delays in production are avoided and expensive equipment replacements that result from unexpected power losses are completely averted. Producers can rely on uninterrupted remote power while completely bypassing the uncertainty of and fluctuating rates from the grid, even in extreme climates.

For environmentally or population sensitive areas, the turbines and generator braking resistors can be fitted with special silencers to reduce the noise emissions to just under 55 dB(A) measured 100 feet from the source. This renders the units virtually inaudible at the boundaries of the sites.

How has MSC membership been of value to your company and the services you provide?

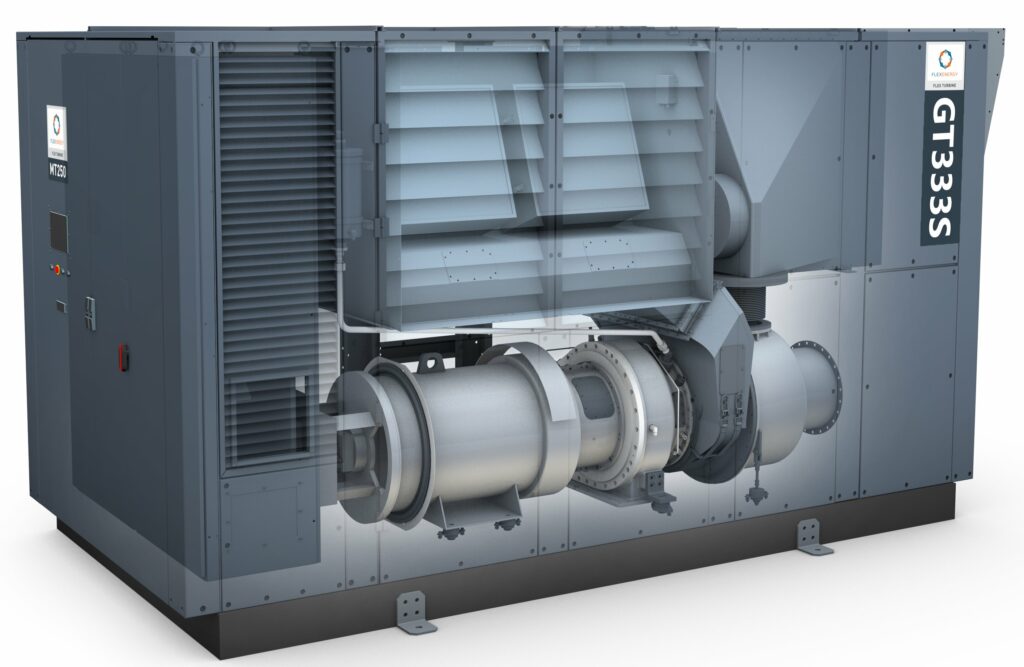

MSC’s objective of creating jobs in the region coincides with Flex Energy Solutions’ cleanest burning power generation equipment in the industry. When National Fuel Gas and Pennsylvania General Energy installed Flex GT333S Turbines in the Marcellus region several years ago, our units were air permit exempt. This is a key factor for how and why we continue to value our relationship. In addition, the various collaborative and sector-specific committees and membership networking opportunities are also of high importance to Flex Energy Solutions. The coalition serves as a valuable and trusted source of industry news and knowledge to any company that is currently running or considering operations in the Marcellus Shale Region.

What is something that you would like a neighbor unfamiliar with the industry to know?

Flex Energy Solutions continues to expand our international presence, strengthen our client partnerships, and broaden our focus to one that helps reduce greenhouse gas from power delivery across industries and across the globe.