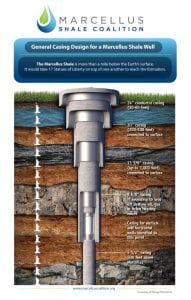

Well Casing

The casing process keeps the well open and protects the earth, similar to the efforts to protect groundwater. The hard metal casing shores up the wellbore and extends through both the vertical (if the well is completed vertically) and the horizontal drilling phases, assuring the long-term integrity of the well from end-to-end. Well casing designs are regulated by the Pennsylvania Department of Environmental Protection (PA DEP) and after a well is in production, operators are required to inspect mechanical well integrity quarterly.

The casing process keeps the well open and protects the earth, similar to the efforts to protect groundwater. The hard metal casing shores up the wellbore and extends through both the vertical (if the well is completed vertically) and the horizontal drilling phases, assuring the long-term integrity of the well from end-to-end. Well casing designs are regulated by the Pennsylvania Department of Environmental Protection (PA DEP) and after a well is in production, operators are required to inspect mechanical well integrity quarterly.

Cement is then pumped down the well under pressure and forced up the outside of the steel casing until the well column is sealed. The casing process ensures that the producing well is isolated from any freshwater zones. This assures during the producing life of the well that fracture fluids, produced brine water and natural gas are isolated and the freshwater bearing zones are protected.

Click here to view an image of a “Cross-Section of a Typical Marcellus Well,” courtesy of Penn State University’s Marcellus Center for Outreach and Research (MCOR).